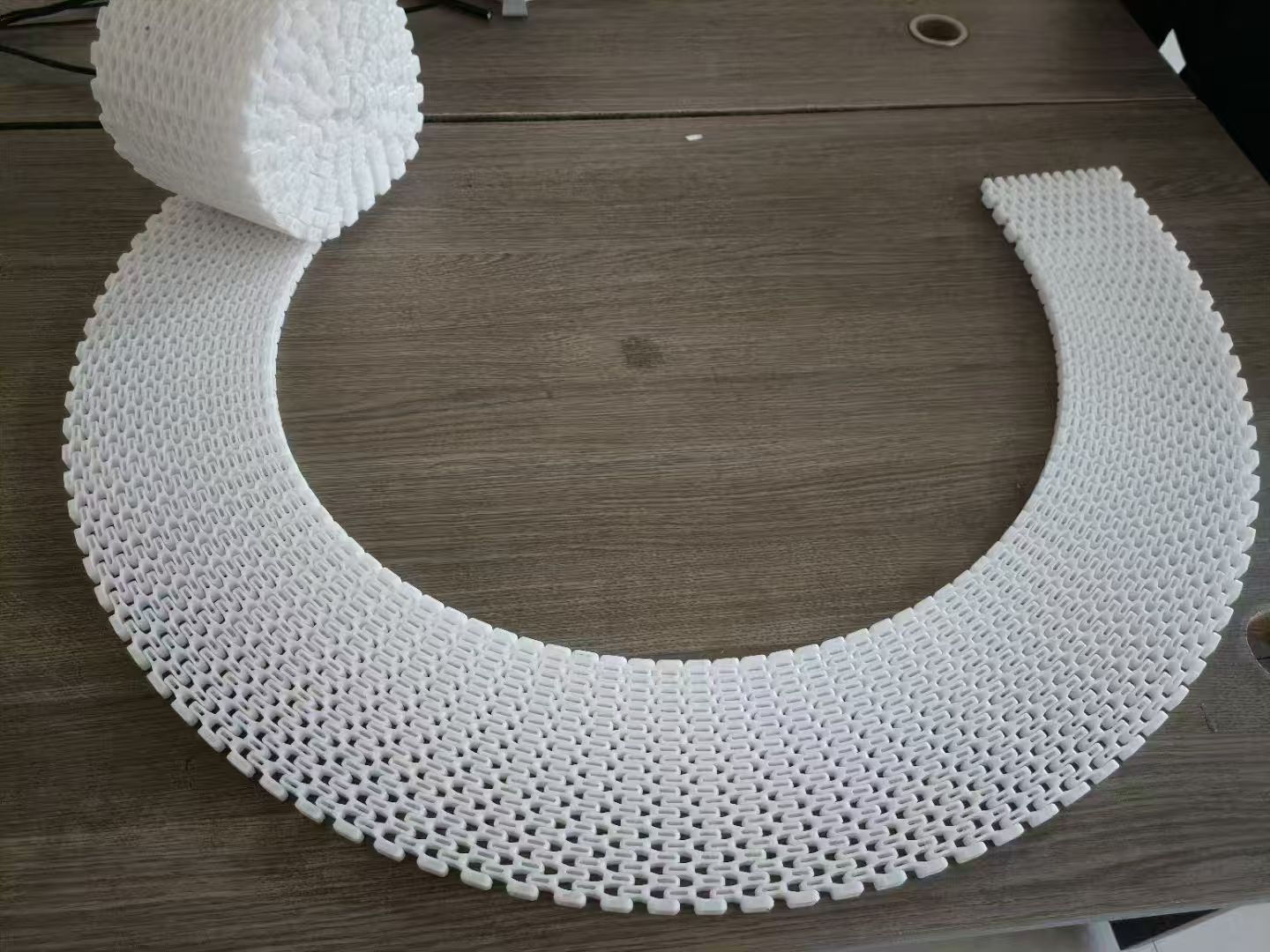

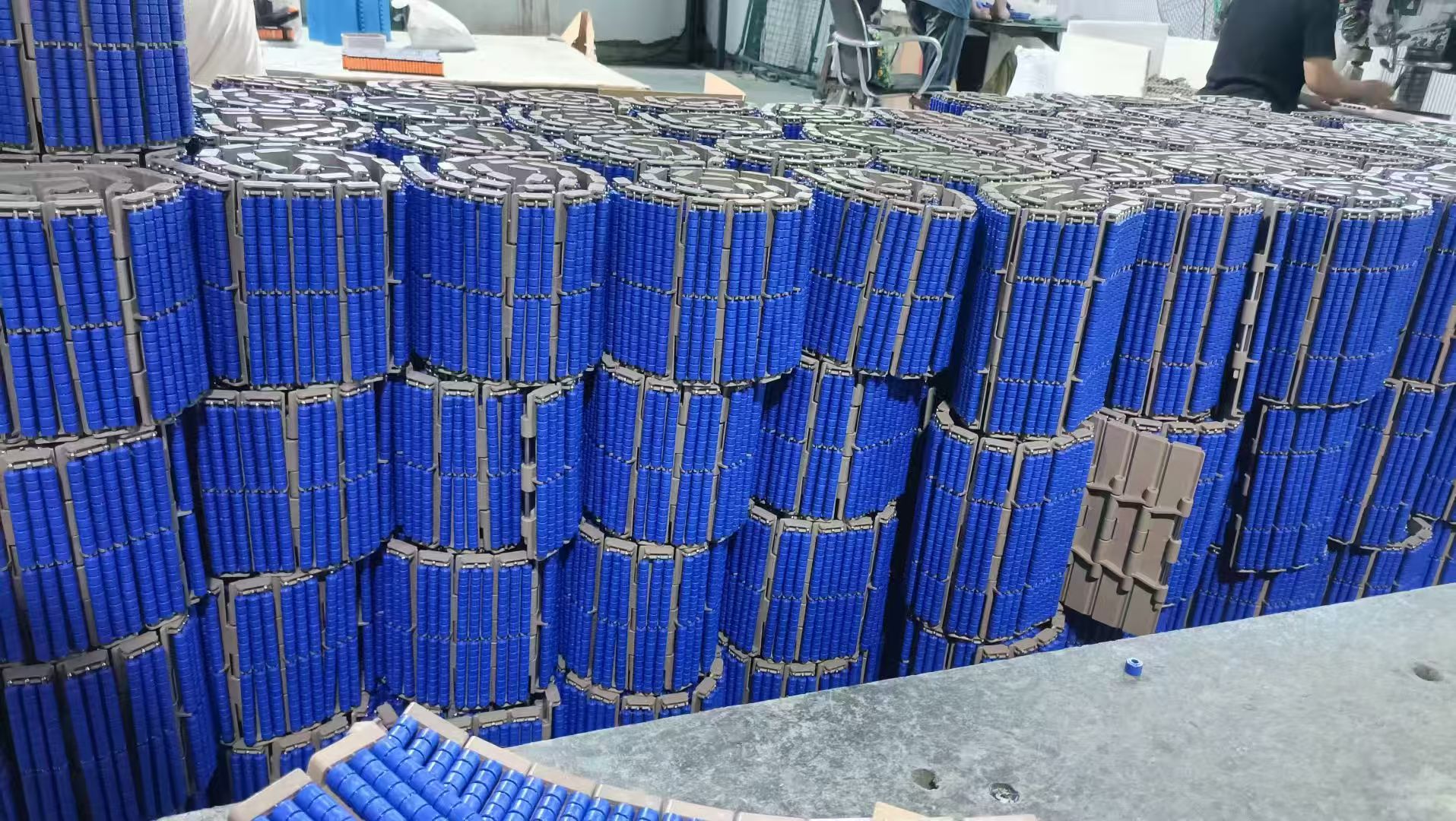

Food and beverage assembly line rubber and plastic product samples

The primary advantages of using rubber and plastic products in food and beverage assembly lines are their safety and cleanliness. Food-grade rubber and plastic materials are non-toxic and odorless, ensuring no harmful substances leach into the food, which guarantees product safety. Their smooth, non-porous surfaces make it difficult for bacteria and dirt to accumulate, so they’re very easy to clean. Additionally, these products have excellent corrosion resistance, allowing them to withstand various cleaning and disinfecting agents, thereby extending their service life.

描述

Rubber and Plastic Products in Food and Beverage Production Lines

Ensuring Food Safety

In food and beverage production, the primary advantage of using rubber and plastic products is safety. Food-grade rubber and plastic materials are specially processed to meet stringent food contact standards, ensuring they are non-toxic and odorless. They do not release harmful chemicals or odors into the food during production, which guarantees the purity of the products and the health of consumers. This also prevents issues like heavy metal leaching or microplastic contamination that can occur with traditional materials.

Facilitating Hygiene and Cleanliness

Given the high hygiene requirements of food and beverage production, a key advantage of rubber and plastic products is their cleanliness. Their surfaces are smooth and non-porous, making it difficult for bacteria, mold, and other microorganisms to stick and grow. During routine cleaning, dirt is easily removed with standard cleaning agents, which significantly reduces the difficulty and time required for cleaning and minimizes the risk of cross-contamination.

Ensuring Durability for Stable Production

The durability of rubber and plastic products is crucial for the continuous operation of food and beverage production lines. These materials offer excellent corrosion resistance, allowing them to withstand long-term exposure to strong cleaning agents, disinfectants, and the acids and alkalis that may be encountered during production. This chemical resistance ensures that components do not easily age, deform, or become brittle, which extends the equipment’s service life, reduces maintenance and replacement costs, and ensures stable and continuous operation of the production line.

评价

目前还没有评价